MOOG G761 Series Servo Valves G761-3033B Direct-Operated Flow Control

MOOG G761 and 761 Series Servo Valves Direct-Operated Flow Control for Analog Signals

2-stage flow control Mechanical Feedback (MFB) Servo Valve

Nozzle-flapper pilot stage technology provides high dynamics, high resolution and low hysteresis

High spool driving forces and rugged design ensures long-life operation

Compact design enables applications with limited footprint

Instrinsically-safe versions (G761K and 761K) available for applications requring products certified for use in potentially hazardous environments

Product Overview

The G761/761 Series Flow Control Servo Valves are throttle valves for 3 and preferably 4-way applications. They are a high performance, 2-stage design that covers the range of rated flows from 4 to 63 l/min (1 to 16.5 gpm) at 35 bar (500 psi) valve pressure drop per spool land. The design is simple and rugged for dependable, long life operation. The output stage is a closed center, 4-way sliding spool. The pilot stage is comprised of a symmetrical, double nozzle dry torque motor. The 2nd stage spool position is controlled by a carbide tipped feedback wire. The carbide ball on the end of the feedback wire is a mandatory design requirement that ensures high accuracy, reliable operation and long service life. All of our Servo Valves are known for high accuracy and reliable operation even in the harshest industrial applications. These valves are suitable for electrohydraulic position, speed, pressure or force control systems with high dynamic response requirements.

Description of Operation

The G761/761 Series Flow Control Servo Valve consists of a polarized electrical torque motor and two stages of hydraulic power amplification. The motor armature extends into the air gaps of the magnetic flux circuit and is supported in this position by a flexure tube member. The flexure tube acts as a seal between the electromagnetic and hydraulic sections of the valve. The 2 motor coils surround the armature, one on each side of the flexure tube. The flapper of the first stage hydraulic amplifier is rigidly attached to the midpoint of the armature. The flapper extends through the flexure tube and passes between 2 nozzles, creating two variable orifices between the nozzle tips and the flapper. The pressure controlled by the flapper and nozzle variable orifice is fed to the end areas of the second stage spool.

The second stage is a conventional four-way spool design in which output flow from the valve, at a fixed valve pressure drop, is proportional to spool displacement from the null position. A cantilever feedback spring is fixed to the flapper and engages a hole in the center of the spool. Displacement of the spool defects the feedback spring which creates a force on the armature/flapper assembly. Input signal induces a magnetic charge in the armature and causes a deflection of the armature and flapper. This assembly pivots about the flexure tube and increases the size of one nozzle orifice and decreases the size of the other.

The differential pressure created by this action causes spool motion. The resulting spool displacement induces a linear force in the feedback wire which opposes the original input signal torque. Spool movement continues until the feedback wire force equals the input signal force.

| Specifications | |

| Hydraulic Data | |

| Rated Flow* | 0.5 to 75 l/min (0.125 to 20 gpm) |

| Standard Configurations | 4, 10, 19, 38, 63 l/min |

| (1, 2.5, 5, 10, 16.5 gpm) | |

| Max. Operating Pressure | 310 or 350 bar (4,500 or 5,000 psi) |

| Performance Data | |

| 100% Step Response** | 5 to 16 ms |

| Frequency Response*** | 120 to 230 Hz |

| Electrical Data | |

| Rated Signal**** | 8 to 200 mA |

| Standard Configurations | 15, 40, 200 mA |

| Physical Data | |

| Size | Size 04 (ISO 10372-04-04-0-92) |

| (Mounting Pattern) | |

| Weight | 1.1 kg (2.4 lbs) |

| Additional Options | High Null Bias, Magnetic Null Adjust, Vented Motor Cap, Special BSA Fit, Parallel Internal Wiring, Reverse Polarity, Very High Response |

| Contact Industrial Application Engineering for additional Flow, Pressure and other options | |

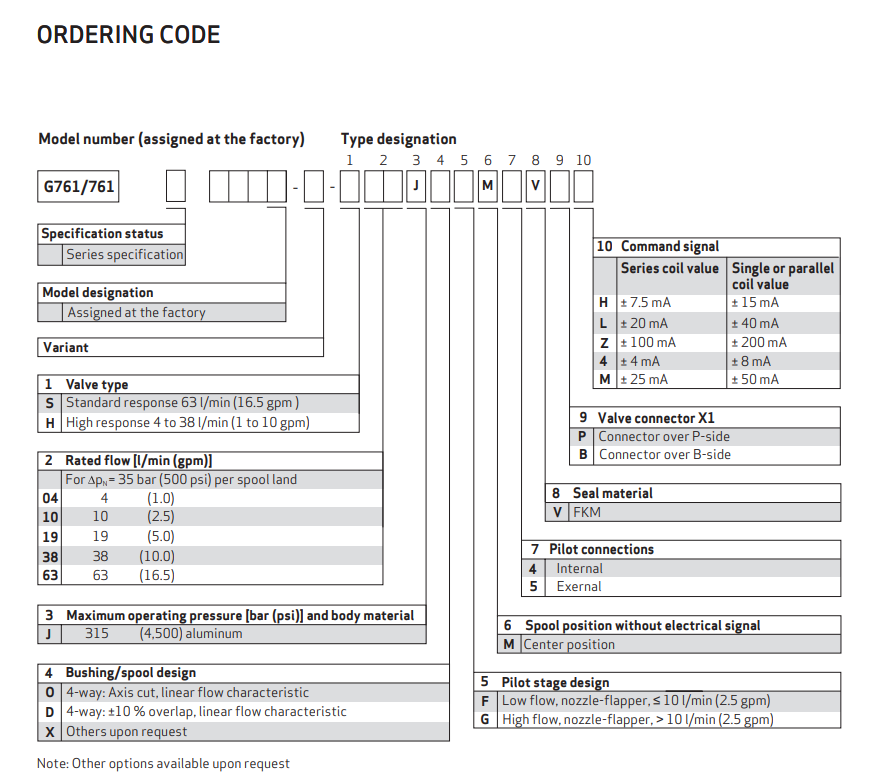

Model Number For example:

G761-3001B

G761-3002B

G761-3003B

G761-3004B

G761-3005B

G761-3600B

G761-3033B

---------------------

We are professional in Industrial Automation & Electrical Distribution instruments, our product mainly including:

Pressure / Temperature Transmitters, Flowmeters, Analyzers, DCS Modules, PLC, Controller, Feild Communicators, Gas Detectors/ Sensors, Safety Barrier and Isolator, Multimeters, Calibrators, Recorder, Soft Starters, Inverters, Positioners, Valves, Circuit Breakers, Contactors, Switches, Power Supply, HMI, Terminal Block, Relay etc.Please feel free to inquiry us by E-mail: lily@hkxytech.com

Our main brands:

Yokogawa, Honeywell, Schneider, Emerson, Rosemount, Fisher, ABB,Siemens, MTL,Pepperl+fuchs, Hirschmann, Phoenix Contact, Weidmuller, ASCO, Norgren, Danfoss, Cisco, MOXA, IFM, Omron, GE, Rockwell(Allen Bradley), EATON, MOOG, Yaskawa, Festo, Fluke, Foxboro, PR electronics, etc.

We promise 100% original brand new with 1-year warranty.

If you are interested in our products, please feel free to contact us!

-----------------------------------------------------------

HONGKONG XIEYUAN TECH CO., LIMITED

Add: 7-A16,Caishen Commercial Plaza,Hankou Railway Station,Wuhan, China

Contact: Ms. Lily

Email: lily@hkxytech.com

WhatsApp/Skype: +86 13789949182

Latest News

-

ORBINOX KP Unidrectional wafer style knife gate valve

January

27, 2026

January

27, 2026

-

ORBINOX VP Bi-directional split body wafer style knife gate valve

January

27, 2026

January

27, 2026

-

ORBINOX AT Uni-directional split body wafer style knife gate valve

January

27, 2026

January

27, 2026